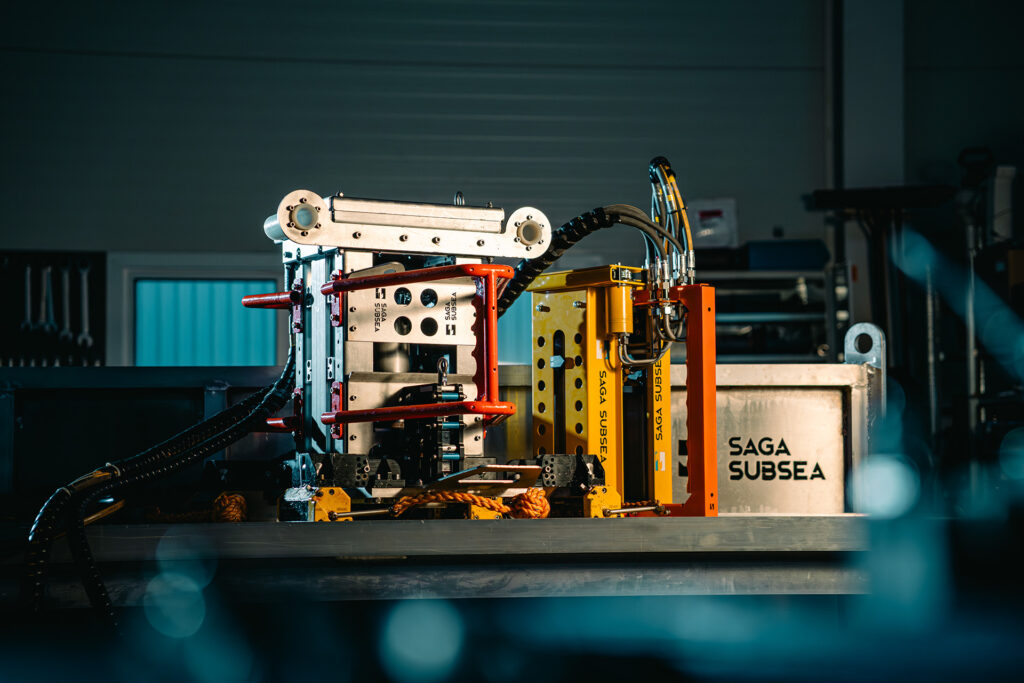

With new, upgraded test facilities and a unique level of expertise, Saga Subsea has achieved results that are hard not to be impressed by.

It all began in 2021 with a customer request for a drilling tool that simply did not exist on the market. The solution became a custom-designed drilling tool developed by Saga Subsea’s workshop and tooling department. Since then, our departmens has seen a growing demand for powerful, highly precise, and tailor-made drilling tools.

– Saga Subsea already possess extensive drilling expertise, and we gain new experiences and knowledge for every tool we produce. In 2025 alone, we have manufactured eight drilling tools. We now offer drilling tools in three different sizes – Ø100, Ø140 and Ø200, says Alexander Alme Rossebø, Head of Workshop and Tooling.

– The newest model, Ø100, is a purely internal initiative where we have invested our own capital to develop the product based on our insight. This marks an important step in Saga Subsea’s evolution, where we are now expanding by also developing solutions on our own initiative in addition to purely customer-specific deliveries, Rossebø continues.