Another successful special solution from our engineering and tooling department.

In the fall of 2023, Saga Subsea received an intriguing challenge from one of our clients, a leading energy operator. The issue? A wellhead on the seabed had sustained significant damage to one of its locking mechanisms. This task demanded both precision and creativity, and Saga Subsea’s engineering team rose to the occasion.

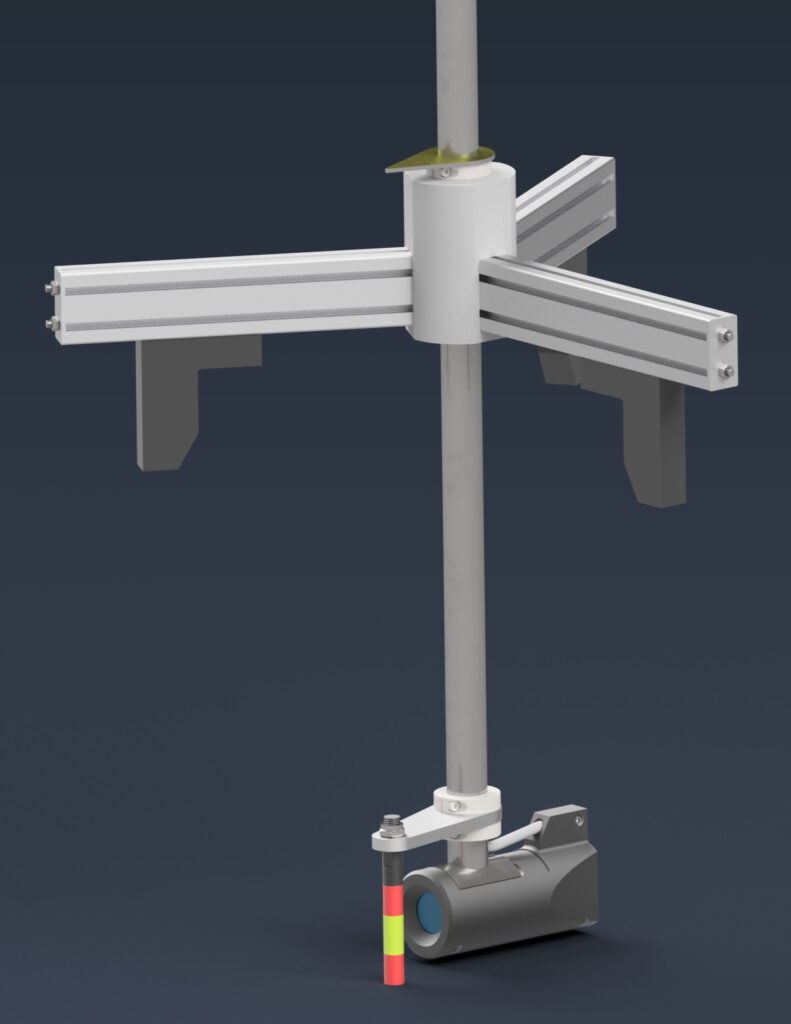

What emerged from this challenge was the Wellhead Dressing Tool, a cost-saving and innovative solution designed to repair and restore damaged wellheads.

A Complex Problem Demanding a Special Solution

When the client approached Saga Subsea, they needed a tool that could precisely address the damaged locking profiles and polish the internal seal surfaces of the wellhead. Lead R&D engineer Walther Skjærvik explains the complexity:

– Repairing these locking mechanisms required an exceptionally precise solution. Achieving perfection was critical to ensure the tool functioned as intended to repair the damage effectively.

To meet these requirements, the team designed a tool using interchangeable diamond grinding stones and polishing pads to achieve optimal results.